The day we’ve been waiting for has arrived. We know results of the Note 7 investigations are ready to be revealed and would be livestreamed over the weekend. We’ve been saying that battery was the likely cause. We also heard of that possibility of a small interior design. In the first few months of this fiasco, most people are saying that battery was the cause. Samsung did change the battery supplies but the same thing happened. More overheating and explosions were reported that prompted the South Korean tech giant to announce a global recall and halt production.

Soon enough, retailers and mobile carriers were offering exchange programs and Note 7 Return Kits while airlines banned the Note 7. The company was busy with the recall and other Samsung businesses were naturally affected.

After weeks of thorough investigations by third parties and experts, the results are in. The main cause: BATTERY. As if we didn’t already know that, the problem has just been made official. In the press conference earlier today, Samsung Electronics’ President of Mobile Communications Business DJ Koh, announced the results of the investigation in a more detailed manner. He also apologized to the Note 7 customers but thanked them for their support and patience.

There were many technical explanations and illustrations delivered by heads of the independent industry groups that launched their own investigations including executives from UL, Exponent, and TUV Rheinland AG. Safety measures taken by Samsung as response to the incidents were also identified.

Samsung SDI and ATL, the battery suppliers, were not directly named but the company put on the blame on manufacturing defects and lapses. That’s something we heard before and we’re surprised that it took them a while to identify the official cause. The suppliers were only identified as “Battery/Company A” and “Battery/Company B”. These are two different companies and what’s interesting is that each made different manufacturing-related problems. There were some missteps along the way that caused the explosions of the lithium-ion batteries.

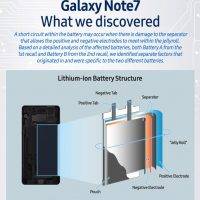

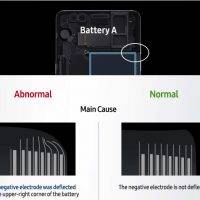

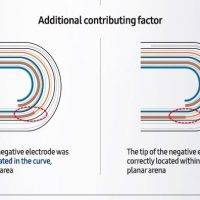

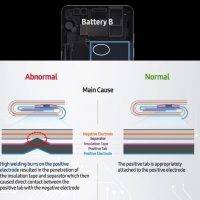

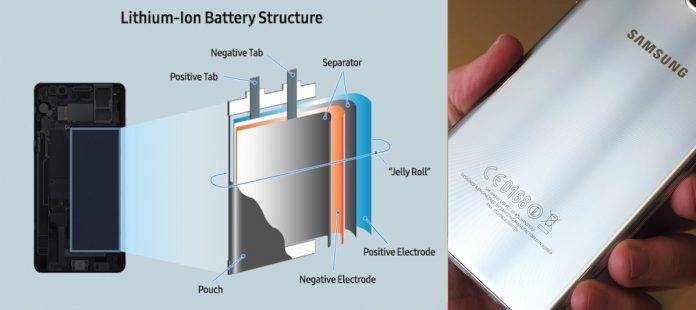

The battery makers employed several layers that keep positive and negative tabs of the electrodes to connect in “jellyroll”. This was to conduct electricity which can short circuit if there is a damage to the separators. Batteries from Company A had bent negative electrodes and incorrectly located tips. As for Company B, the welding burrs were very high, causing the positive tab for the positive electrode pierce the separator. Both batteries resulted to short circuiting and fires eventually.

So Samsung wasn’t exactly at fault. We can blame the battery makers and as confirmed by several tests. But another big problem was, Samsung was not able to identify these issues before the public launch when it should have been tested thoroughly.

Samsung definitely learned from this situation. To prevent such from happening again, the South Korean tech giant will be implementing a “broad range of internal quality and safety processes” that will improve product safety. New protocols were added like the ‘8-Point Battery Safety Check’ and several multi-layer safety measures. To ensure that the batteries are really safe and ready in the future, the Battery Advisory Group was formed. This group includes academic and research experts plus external advisers who will check on battery safety and innovation.

So there, BATTERY is to blame.

SOURCE: Samsung