HTC continues to impress the mobile industry with the latest HTC U11. After several weeks of rumors, leaks, and teasers, the Taiwanese tech giant officially announced its new premium flagship smartphone. It was better than expected and the device quickly took the crown off the Google Pixel on DxOMark with a score of 90. We saw a lot of squeezing actions and finally got our hands on one. We’re quite impressed with the phone but we’re still working on a more detailed analysis. We’re actually expecting in the coming days related videos that test the phone’s durability, speed, or performance.

The company is celebrating its 20th anniversary and to mark the milestone, HTC is showing off where its products are made in Taiwan. For the first time, HTC has invited some people to three of its facilities—the factory, Design Studio, and the Research & Development facility. These locations are where the HTC U11 were manufactured, designed, and where the audio and imaging technologies were developed.

A group of media people was invited and our friends at SlashGear were lucky to be part of the tour. The photos published here were not taken by the visitors but were official images from HTC. We find it interesting that guests weren’t able to take their own photos during the tour. We understand why the OEM had to do it but what’s the point of inviting people if you don’t want them to record the experience.

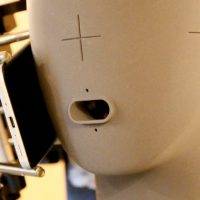

It is one long factory tour but worth it because it is the first time in two decades that HTC allowed the media. Guests were presented each stage of the process. The gadget production line was showcased. The visitors were shown off how the U11 started as a “slab of substrate” which was then fed the different components like the chips, SIM trays, and processors.

The units then go through a soldering tunnel and then out into trays for testing numerous times. Doing so lets the phones get checked after each stage. After this processor, the completed boards are then sent to a new location to add the frame, display, and battery. Robots and employees work together to finish the assembly from screwing to gluing to putting together the parts. Other components like the LED flash, Bluetooth, and WiFi are then added. Humans test about 10% of each batch of phones to ensure they are ready before shipment.

HTC boasts of the “Liquid Surface” design language used on the new U11. The whole phone is a product of many stages of working on the Gorilla Glass 5 that includes heating, bending, and then milling the glass to create the 3D curves. As for the back cover, it is a product of a process called Optical Spectrum Hybrid Deposition to layer the refractive minerals.

HTC has always been known to be “quietly brilliant” but this move to invite the media team may offer some changes to how people perceive the brand. HTC is brilliant but it shouldn’t be quiet. Now we’ve got a glimpse of how the company designs and manufactures the products to ensure premium quality all the time.